Industrial safety is vital in ensuring the profitability of oil-refining and petrochemical industries. A high level of industrial safety in hydrocarbon processing is mainly ensured by machinery and asset reliability management. Risk-based reliability is currently the most popular approach, outpacing all other practices in implementation in the oil and gas downstream. Ensuring a high level of safety, reliability, and operational efficiency of processing for 40 years is the centerpiece for all managers and specialists of the Pavlodar Petrochemical Plant, LLC (hereinafter PPP), the leader of the Kazakhstan Oil & Gas downstream industry. That is why PPP management and personnel greatly supported the production safety, machinery reliability, and operation efficiency improvement strategy based on the industrial risk management initiated by KazMunaiGas, JSC.

It is widely acknowledged that out of the two risk multipliers, it is most difficult to calculate the probability of an adverse event such as an accident, downtime, or unscheduled maintenance of equipment or the entire facility. On the one hand, calculating the probability of equipment failures according to manufacturers’ statistics does not consider the current operating conditions, quality of the process design, correctness of the equipment selection, and its installation trueness. On the other hand, own statistics are often insufficient for correctly calculating failure probability. In addition, the only effective strategy for asset reliability management is reducing the risk of failures since the rest of the known methods are not applicable in hazardous facilities.

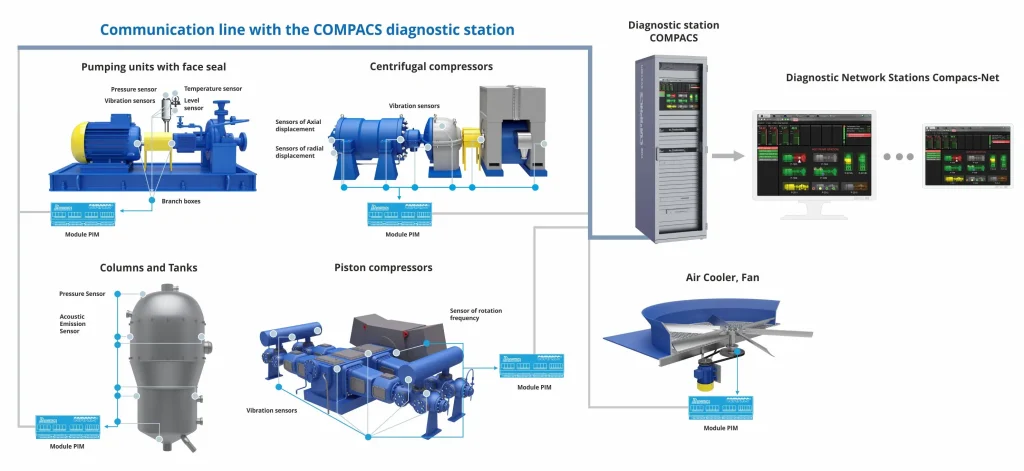

Having scrutinized this issue, the management of PPP concluded that achieving an absolute reduction in the number of equipment failures in operation is possible only by using modern systems to monitor the technical condition of equipment in real-time. In 2015, PPP launched the COMPACS® system installation, which implements the concepts of the industrial Internet of Things and Industry 4.0. The system uses artificial intelligence to provide prescriptive analytics on the equipment’s state to management at all levels.

The Real-Time Diagnostic COMPACS® System Implementation Case

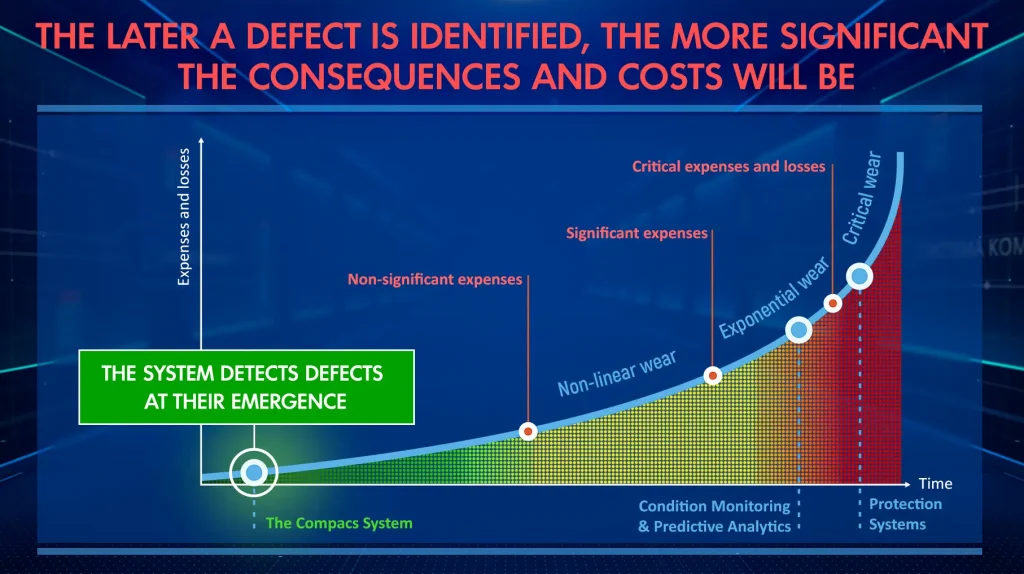

Among the advantages of the COMPACS® equipment monitoring system over other rotating and fixed equipment reliability solutions, it is necessary to note an embedded physics-based artificial intelligence for detecting emergent defects and malfunctions of equipment in real time. The system’s artificial intelligence detects the vast majority of rotating equipment failures at their emergence when destructive forces have just begun to degrade the equipment, and there is a chance to prevent its breakdown and even its redundant maintenance. Moreover, the system identifies the processes of cracking, the occurrence of fistulas, and leaks in the static equipment in operation. Eliminating destructive forces as early as possible prevents most of the adverse consequences of failures, such as an accident or downtime of the processing facility. Furthermore, it reduces the cost of equipment repair repeatedly.

Centrifugal Machines

BEARING

- lack of lubrication

- misalignment

- looseness

- outer race fault

- outer race deformation (out-of-roundness, pitting, spalling)

- inner race fault

- inner race deformation (out-of-roundness, pitting, spalling)

- rolling element fault

- cage fault

- bearing oil-film failure

TEMPERATURE

- overheating

- uneven heating

- intolerable gradients

HYDRO-GAS-DYNAMICS

- cavitation

- hydraulic impact

- air break

MACHINE TRAIN

- shaft misalignment

- rotating mass imbalance

- lubrication problems

- loosened fastening to the base and attached structures

- gear faults

MACHINE

- fastening problems

- rotor imbalance

- impeller faults

- shaft cut

- intolerable rotor runout

- intolerable axial thrust

- coupling fault

ELECTRICS

- current overload

- voltage unbalance

- stator faults

- rotor/stator misalignment

- squirrel cage faults

- air gap eccentricity

- rotor eccentricity

Piston Machines

VALVE

- broken springs, plates

- leakage

- condensate flow-in (hydraulic impact)

- process upset

CYLINDER PISTON GROUP

- ring wear

- liner wear

- part loosening

- lack of lubrication

- condensate flow-in (hydraulic impact)

- process upset

ELECTRICAL EQUIPMENT

- defects in cells, contactors, transformers, etc.

- insulator contamination

- partial discharge in insulation

- stator iron sparking

- contact sparking

- corona discharge

SLIDER-CRANK MECHANISM

- babbitt wear

- part loosening

- lack of lubrication

- increased rod-slider clearance

MAIN BEARING

- babbitt wear

- looseness

- lack of lubrication

ROD

- gland wear

- bent rod

- broken rod

MACHINE TRAIN

- loosening of body components

- rotating mass imbalance

Another vital advantage of the system is the objectivity of examination of the equipment’s technical state and the employees’ contribution to ensuring asset reliability. Everyone involved, from the operator and mechanic with an electrician to the management, becomes accountable for their own decisions. The most important advantage of the system is that it makes the operation of the equipment of the entire processing facility observable. Therefore, the facility reaches sustainable, accident-free operation with the most extended uptime.

The selection of the COMPACS® system to improve the asset reliability, maintenance management, and operational efficiency of PPP was not spontaneous. Cooperation with the system developer began in 2003 when PPP installed the first two systems in the maintenance workshop for roller bearings checking and dynamic balancing of cantilever pumps based on automatic vibration analysis. The systems’ installation made it possible to eliminate repeat repairs and purchase only high-quality bearings from suppliers, returning others without payment.

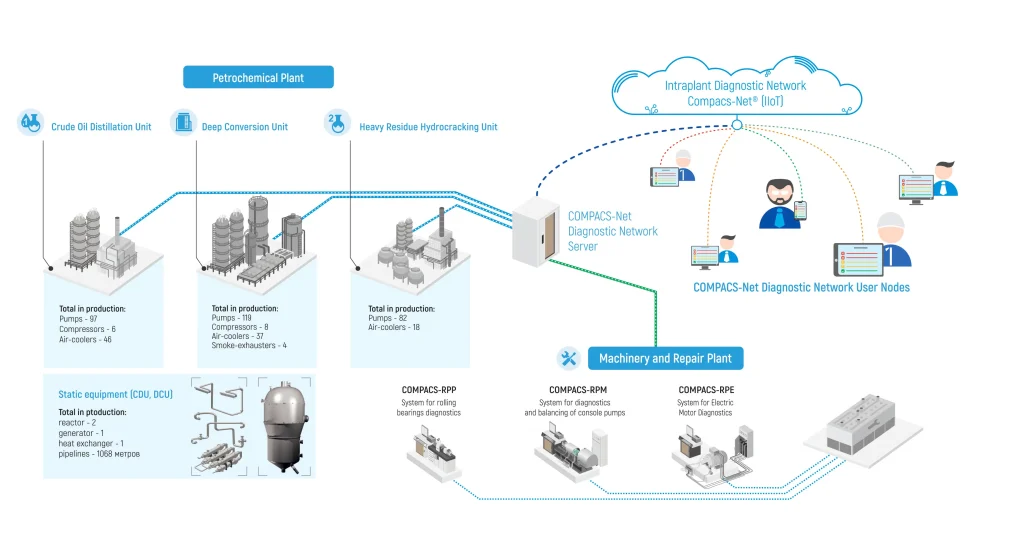

In 2015-2016, using their scientific research and significant experience in refinery reliability management, the specialists of the system developer introduced the Program for the transition of PPP to the SROMM technology of Safe Resource-saving Operation and Maintenance of Machinery. Over the following three years, 417 pieces of rotating equipment and 25 most critical pieces of static equipment have been equipped with the COMPACS® system at the main processing facilities, a crude distillation complex (KPPN), a deep oil conversion complex (KGPN) and a heavy oil residue processing complex (KPTNO).

Monitoring System Implementation Results

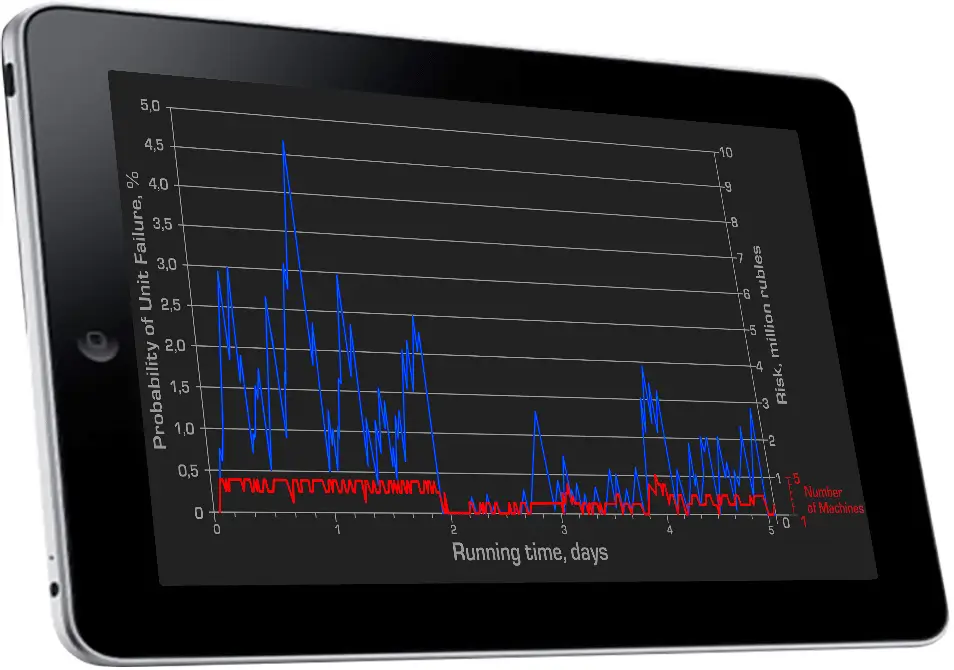

As a result of equipping these processing units with the COMPACS® system, the basic level of the failure omission probability of the most critical equipment was radically reduced at KPPN to 1.2%, at KGPN to 2.3%, and at KPTNO to 1% respectively. Therefore, the reduced failure omission probability positively impacted the total value of the basic risk of operation of the mentioned units, which decreased to 9.3 billion tenges. The annual economic impact from the system’s prescriptions exceeded the expected under the Program and amounted to 1.1 billion tenge. The net present value reached 5.7 billion tenges, which ensured the internal rate return of the project was 66%.

In 2017 alone, PPP personnel prevented around 150 failures of the most critical and critical equipment (categories I and II), the sudden failure of which could lead to an accident and unit downtime. The employee discipline has significantly grown operators and maintenance personnel do not wait for the machinery to reach the unacceptable state to dispatch them to the maintenance workshop but are looking for ways to reduce destructive forces and extend their uptime as soon as possible.

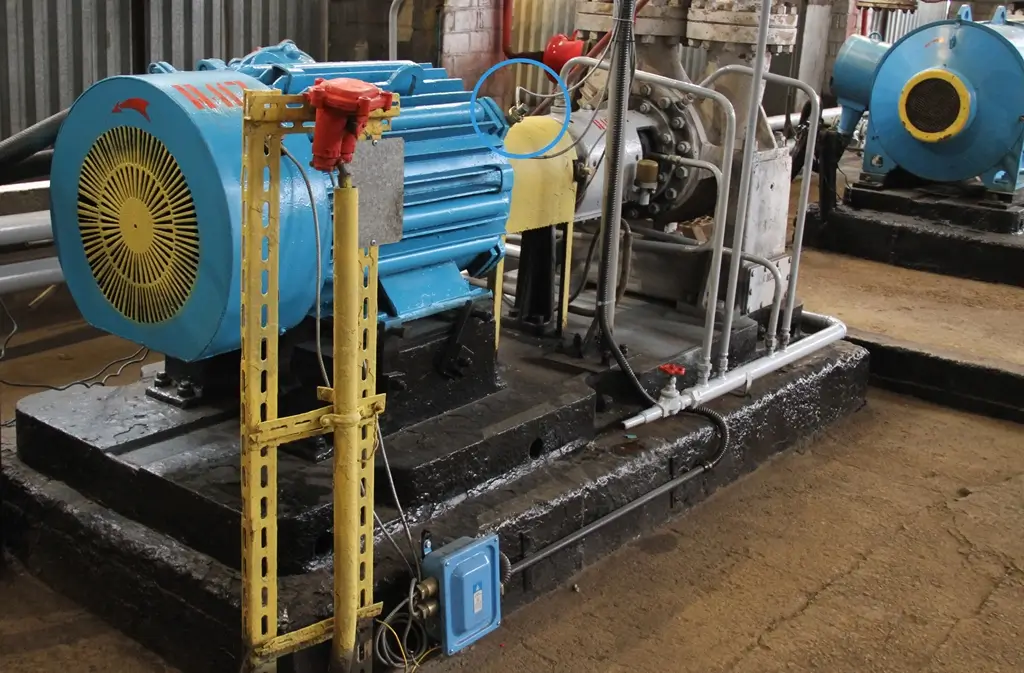

An excellent example of personnel involvement in asset reliability management and operational efficiency improvement is the case of the safe resource-saving operation of KGPN equipment, where the technological personnel independently carried out maintenance, extending the lifespan of the pump unit. On November 15th, 2017 at 22:18, the KGPN operators confirmed the notice of the COMPACS® system on the transition of the N-111/R pump unit to the technical state “Unacceptable” demanding to check the motor front bearing and its greasing. According to the standard operating procedure (SOP), the process personnel attempted to extend the uptime of the pump unit by slightly changing its operating mode. Nonetheless, these alterations did not impact degradation significantly since the pump unit continued to be operated with the Action Required technical state.

Enhancing Asset Reliability

Only after greasing the front bearing, did the motor reach an acceptable technical state, and its vibration dropped six times. It is important to note that the personnel carried out all activities on their own at night when the leading specialists were absent at the plant. Such a situation was utterly impossible before the systems were implemented.

An equally important static equipment failure was also prevented. In early December 2017, the system issued the prescription demanding to check section AE07 of pipeline L303/2. As shown in Section 1, the diagnostic parameter associated with the valve’s leak has crossed the threshold and reached an Unacceptable level between 05.12.2017 and 15.12.2017. The personnel quickly tightened the shutoff valve but could not eliminate the leak. Only in two weeks, on 25.12.2017, the threaded connection of the valve was pull-broached, which solved the problem.

Prescriptive analytics from the COMPACS® system focuses the personnel’s attention on the most problematic pieces of equipment. It accurately identifies emerging destructive forces that lead to certain defects and malfunctions and allows the elimination of them early, preventing the defects’ development and the equipment’s degradation. The involvement of all personnel in improving the reliability of equipment is a decisive factor for the successful implementation of the risk-oriented reliability management program and for improving operational efficiency.

Increasing Equipment’s Reliability and Uptime

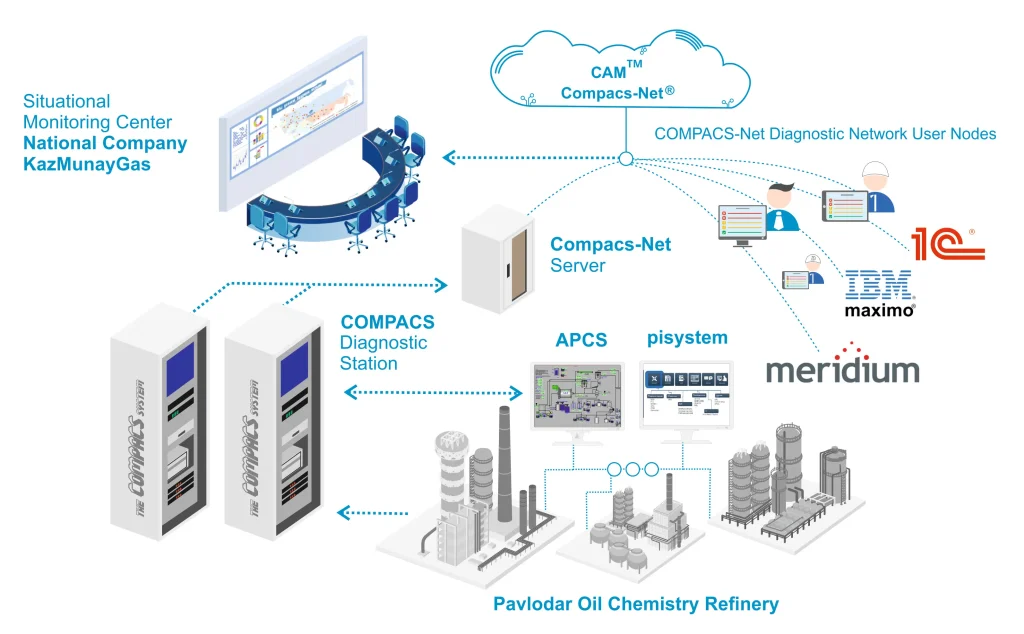

Getting such impressive results in risk-oriented asset reliability management and operational efficiency based on the COMPACS® system’s implementation at PPP, KazMunayGas JSC is considering scaling that project to the entire PPP facility and other owned refineries.

Advanced Machinery Reliability Solutions

Nowadays, KazMunayGas JSC plans to integrate the technical state monitoring systems, distributed control systems, computerized maintenance management system, and a risk management system into a single data center for the monitoring center (TMC) of reliability and operational efficiency of the refinery. TMC will allow to gather and distribute in realtime among authorized employees prescriptive and predictive analytics on the reliability of machinery and static equipment, availability and technical readiness of processing units, their power consumption, processing modes, indicators and diagrams of quantity, quality, timeliness, and efficiency of maintenance, to monitor the risk of processing units and refineries operation.

The implementation of this project during the anniversary year of PPP will not only motivate the enterprise’s employees. Still, it will also ensure the long-term leadership of the petroleum refining industry of the Republic of Kazakhstan in the adoption of cutting-edge technologies in everyday life.

In fact, the Pavlodar petrochemical plant brings to life the motto of Dynamics Scientific, Inc.: “Through reliability and quality, we move towards resource-saving safety, efficient manufacturing, and the prosperity of society.”

Explore Our Case Studies

Pump Monitoring Case - The COMPACS System Resolves Critical Failures

11/20/2024

Industrial pumps are vital for operations in industries like oil and gas, where equipment reliability and efficiency are non-negotiable. Unplanned...

Read More

Case Study: Condition-Based Maintenance Of an Oil Pump

06/28/2024

In this case study, we present a condition-based maintenance case using the real-time diagnostic COMPACS system. Pump Monitoring In the...

Read More

The COMPACS® System in Action: The Bottleneck's Eliminating Case

06/21/2024

We will present bottlenecks eliminating case study on how to remove bottlenecks. Here, you see two trends of different vibration...

Read More