A List Of Defects And Malfunctions of Rotating Equipment

Which The Real-Time Diagnostic COMPACS® System Identifies In Rotating Equipment

Book a MeetingRotating Equipment Monitoring

The COMPACS® system detects most of the failures of rotating equipment. On the left side, there’s a list of defects detected in centrifugal machines. On the right, there’s a list of malfunctions in reciprocating compressors. Almost all often appearing defects can be detected as early as possible in a very reliable way. Physics-based artificial intelligence utilizes scientifically proven knowledge of degrading various nodes of different machines rather than poor and handmade statistics. Each defect or malfunction has its unique set of parameters that not only reliably detect the malfunction itself but also allow the determination of the stage of its degradation using specific thresholds. Thus, if the system identifies an informative feature in a vibration signal, the defect exists, and its stage of degradation has been determined.

Centrifugal Machines

BEARING

- lack of lubrication

- misalignment

- looseness

- outer race fault

- outer race deformation (out-of-roundness, pitting, spalling)

- inner race fault

- inner race deformation (out-of-roundness, pitting, spalling)

- rolling element fault

- cage fault

- bearing oil-film failure

TEMPERATURE

- overheating

- uneven heating

- intolerable gradients

HYDRO-GAS-DYNAMICS

- cavitation

- hydraulic impact

- air break

MACHINE TRAIN

- shaft misalignment

- rotating mass imbalance

- lubrication problems

- loosened fastening to the base and attached structures

- gear faults

MACHINE

- fastening problems

- rotor imbalance

- impeller faults

- shaft cut

- intolerable rotor runout

- intolerable axial thrust

- coupling fault

ELECTRICS

- current overload

- voltage unbalance

- stator faults

- rotor/stator misalignment

- squirrel cage faults

- air gap eccentricity

- rotor eccentricity

Piston Machines

VALVE

- broken springs, plates

- leakage

- condensate flow-in (hydraulic impact)

- process upset

CYLINDER PISTON GROUP

- ring wear

- liner wear

- part loosening

- lack of lubrication

- condensate flow-in (hydraulic impact)

- process upset

ELECTRICAL EQUIPMENT

- defects in cells, contactor, transformer, etc.

- insulator contamination

- partial discharge in insulation

- stator iron sparking

- contact sparking

- corona discharge

SLIDER-CRANK MECHANISM

- babbitt wear

- part loosening

- lack of lubrication

- increased rod-slider clearance

MAIN BEARING

- babbitt wear

- looseness

- lack of lubrication

ROD

- gland wear

- bent rod

- broken rod

MACHINE TRAIN

- loosening of body components

- rotating mass imbalance

A Blower

A Fin Fan

A Centrifugal Compressor

A Reciprocating Compressor

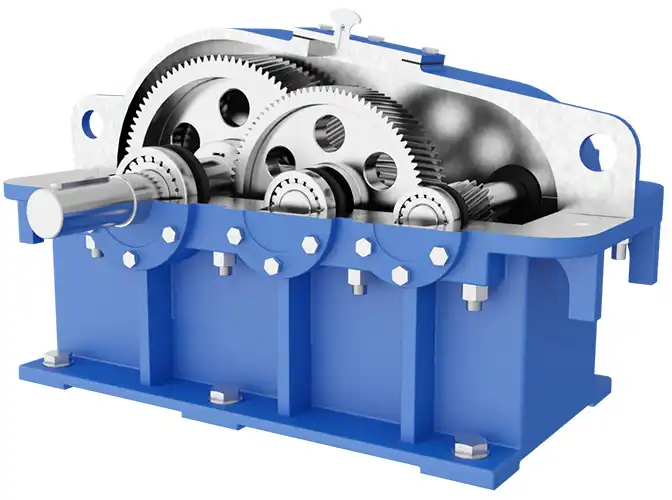

A Gear Box

A Pump

Real-Time Prescriptions

Patented physics-based AI generates real-time prescriptions and predicts residual lifespan, which allows eliminating equipment failures and avoiding redundant maintenance. The COMPACS® system monitors every rotating equipment at the facility including reciprocating, centrifugal, and screw compressors, pumps, fin fans, gears, motors, turbines.